- SPT Laser Technology Co., Ltd.

- 3201, Dongjiang Star Commercial Center, No.8 Hongfu West Road, Wanjiang District, Dongguan City.

- +86-769-26380380 Ext. 8012

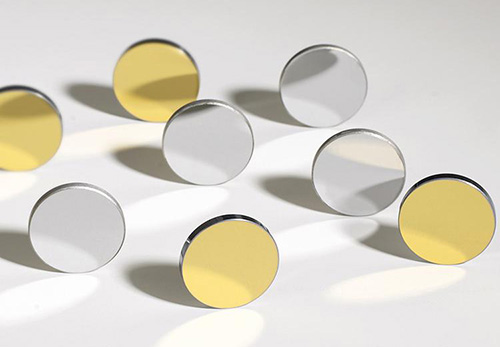

CO2 Laser Mirriors, Laser Optics

SPT CO2 laser mirrors feature high reflectivity and usually use molybdenum (Mo), copper (Cu) and silicon (Si) as substrates. Customer can choose an appropriate laser mirror according to your laser processing requirements.

- Mo mirror: Molybdenum mirror is suitable for harsh working environments with long lifespan. It can withstand high power laser, feature high abrasion resistance and doesn’t need coatings. However, molybdenum mirror’s reflectivity is lower than other laser mirrors.

- Cu mirror: Copper mirror is mainly used for high-power CO2 lasers.

- Si mirror: Silicon is the most common substrate of coated laser mirrors. SPT Silicon mirror has excellent optical thermal performance and industry leading reflectivity >99.8%.

Technical parameters

| Substrate: silicon, molybdenum, copper | Size tolerance: +0.0/-0.1mm |

| Thickness tolerance: ±0.1mm | Surface accuracy: λ/4@632.8nm |

| Surface finish: S1:40-20 | Parallelism: < 1 arc min |

| Effective aperture: >90% | Bevel: 0.2×45° |

| Coating: MMR, EG, ES, PG |

Model specifications

| Model | Material | Diameter (mm) | Thickness (mm) | Reflectivity (%) |

| SPT0.50-0.08 | Silicon | 12.7 | 2 | >99.5 |

| SPT 0.61-0.08 | Silicon | 15.4 | 2 | >99.5 |

| SPT 0.71-0.09 | Silicon | 18.05 | 2.5 | >99.5 |

| SPT 0.75-0.12 | Silicon | 19.05 | 3 | >99.5 |

| SPT 0.78-0.12 | Silicon | 20 | 3 | >99.5 |

| SPT 0.98-0.12 | Silicon | 25 | 3 | >99.6 |

| SPT 1.0-0.12 | Silicon | 25.4 | 3 | >99.8 |

| SPT 1.10-0.12 | Silicon | 27.94 | 3 | >99.6 |

| SPT 1.20-0.12 | Silicon | 30 | 3 | >99.8 |

| SPT 1.50-0.16 | Silicon | 38.1 | 4 | >99.8 |

| SPT 2.0-0.19 | Silicon | 50.8 | 5 | >99.8 |

| SPT M-20-3.0 | Mo | 20 | 3 | >96 |

| SPT M-25-3.0 | Mo | 25 | 3 | >96 |

| SPT M30-3.0 | Mo | 30 | 3 | >96 |